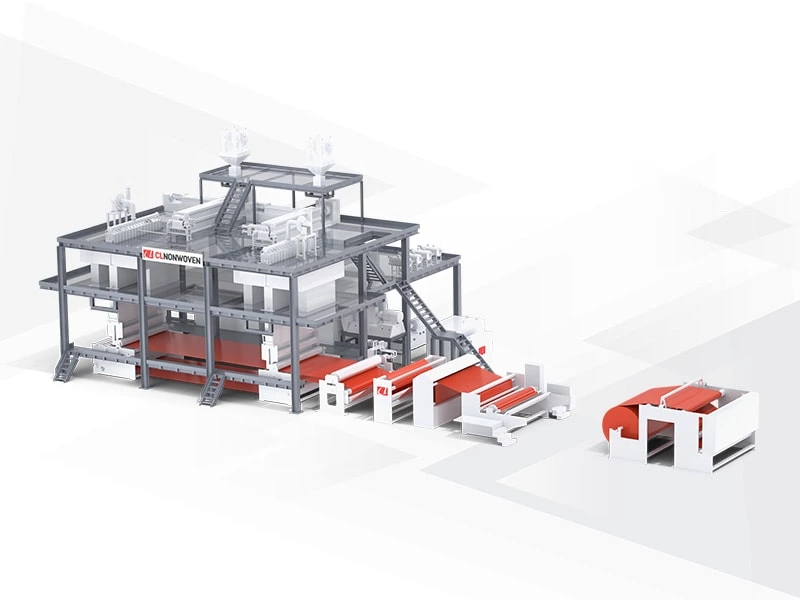

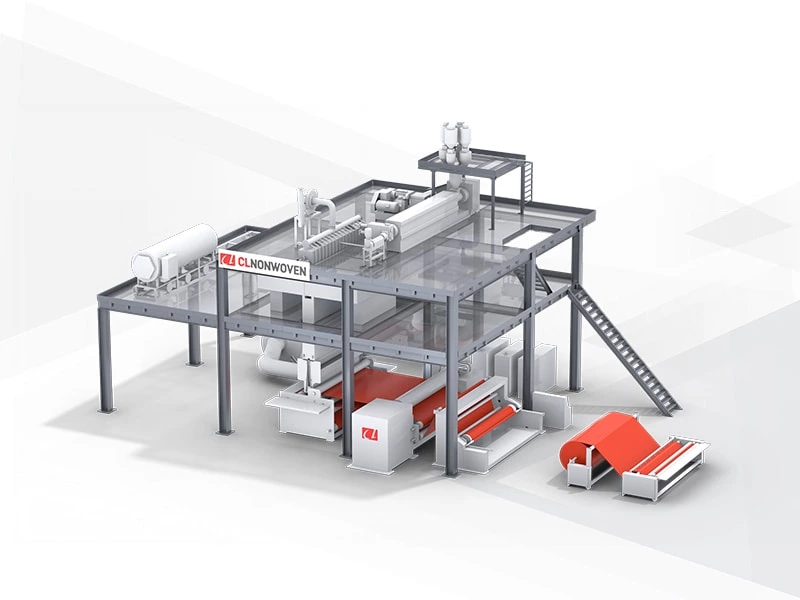

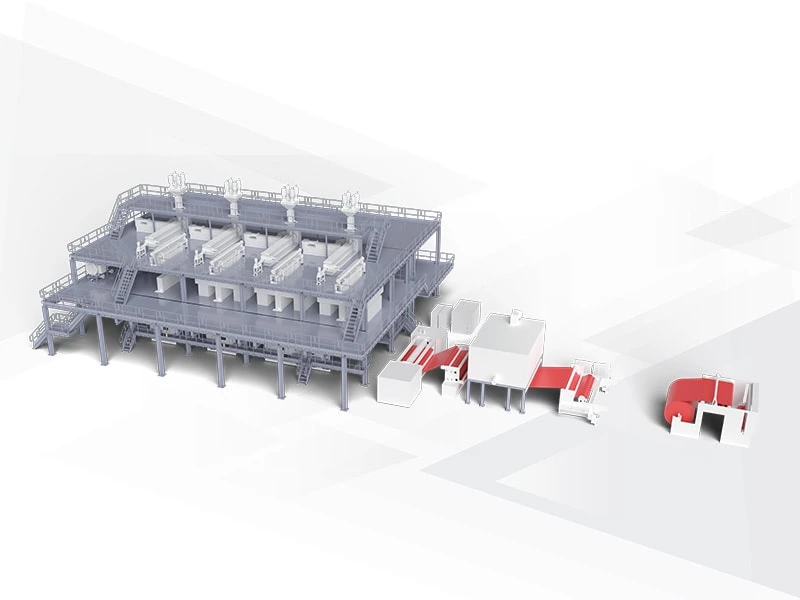

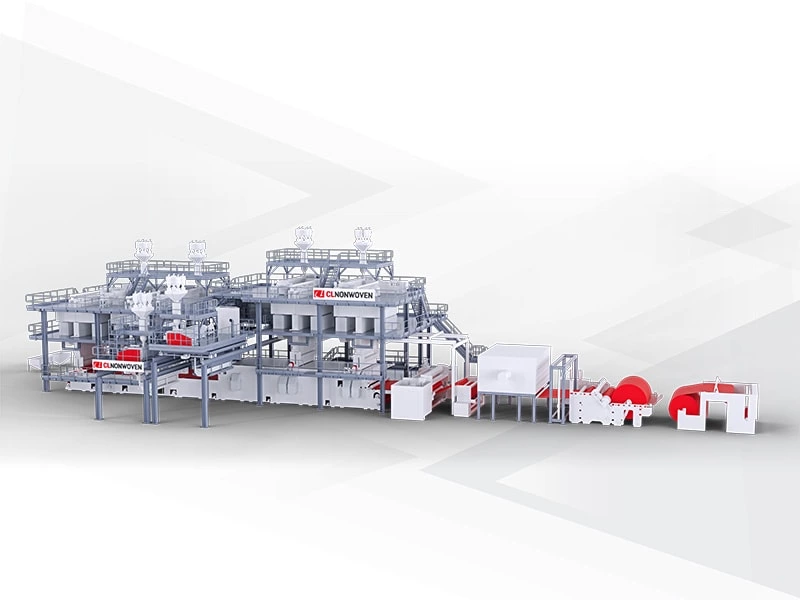

خط إس إس سيبانبوند

تتميز الأقمشة غير المنسوجة المصنوعة من الفولاذ المقاوم للصدأ المزدوج بمرونتها العالية ومثالية للتطبيقات في الصناعات الطبية والصحية. تُستخدم في منتجات مثل القبعات الجراحية، والعباءات، والأقنعة، والملابس الواقية، والأغطية الجراحية، وأغطية الحفاضات العلوية والخلفية للأطفال، وغيرها.

المواصفات التقنية لآلة تصنيع الأقمشة غير المنسوجة بخط سبانبوند SS

| النموذج | العرض الفعّال | كثافة القماش GSM | سرعة الآلة | المادة الخام | القدرة الإنتاجية |

| 1600 SS | 1600 | 8-80gsm | 450m/min | PP Chips | 10 Ton/Day |

| 2400 SS | 2400 | 8-80gsm | 450m/min | PP Chips | 15 Ton./Day |

| 3200 SS | 3200 | 8-80gsm | 450m/min | PP Chips | 20 Ton/Day |

نظرة عامة على خط الإنتاج

تُستخدم هذه الآلة لتصنيع الأقمشة غير المنسوجة من خلال عملية غزل PP، وتشكيل الشبكة، والربط الحراري. تعتمد بشكل أساسي على مادة PP كمادة خام رئيسية، إلى جانب إضافات مثل دفعات الألوان الرئيسية، ومضادات الأكسدة، وعوامل مقاومة التلبد، ومثبطات اللهب. يتميز خط الإنتاج بقدرته على إنتاج أقمشة سبانبوند غير منسوجة من نوع PP بألوان وخصائص مختلفة، مما يجعلها مناسبة لتطبيقات متعددة.

تصنيف SS:S1 → S2 من جهاز تشكيل الشبكة باتجاه المكبس

المتطلبات العامة للمعدات الرئيسية لنظام سبانبوند

1. نظام الجرعات (2 مجموعات)

يستخدم كل نظام تغذية أوتوماتيكية من نوع شفط الضغط السلبي. أنبوب التغذية مصنوع من الفولاذ المقاوم للصدأ بسماكة 1 مم. يوفر نظام الجرعات واجهة عملية للتحقق من المعدات الرئيسية، ويتم إخراج إنذار الأعطال إلى لوحة التحكم الخاصة بالمعدات الرئيسية لتسهيل الفحص.

2. الطارد اللولبي (2 مجموعات)

وظيفة الجهاز وتركيبه: يُستخدم هذا الجهاز بشكل أساسي لضغط وإذابة رقائق PP. يتكون من ناقل الحركة، المخفض، اللولب، رأس الخلط، الغلاف، السخان الخزفي، الإطار، إلخ. ومجهز بنظام تحكم أوتوماتيكي في درجة الحرارة، ونظام تبريد، ونظام إنذار. يعتمد النقل الرئيسي على نظام تحكم بتردد التيار المتردد. يعتمد التحكم في درجة الحرارة لكل منطقة على وحدة التحكم في درجة الحرارة، الترحيل الحالة الصلبة، والمزدوجة الحرارية Pt 100 لتشكيل نظام تحكم مغلق في درجة الحرارة.

3. الطارد لإعادة تدوير المواد (2 مجموعات)

وظيفة المعدات وتركيبها: لإعادة تدوير المواد الحافة. تتكون من المسمار، والكم، ورأس التفريغ،

مرشح الذوبان، جهاز النقل، نظام التسخين، جهاز العزل الحراري، الإطار، نظام التحكم في درجة الحرارة والضغط، بكرة تغذية المواد الحافة وجهاز عجلة التوجيه، إلخ... باستخدام تنظيم سرعة تحويل تردد المحرك المتردد، يعتمد التحكم في درجة حرارة كل منطقة على وحدة التحكم في درجة الحرارة، مرحل الحالة الصلبة، الثرمستور البلاتيني Pt 100 لتشكيل نظام حلقة مغلقة للتحكم في درجة الحرارة. تم تجهيز رأس التفريغ بصمام فحص، مع شاشة ضغط الرأس، النوع الجديد من السهل التغذية ويمنع إصابة اليد، يتم التحكم في منفذ التغذية بواسطة محول تردد سيمنز.

4. فلتر الذوبان (2 مجموعات)

متصل بالطارد مباشرة عبر شفة، ويتكون من مجموعتين من وحدات الفلترة. تحتوي كل وحدة على قناتين مخروطيتين.

5. مضخة الغزل وجهاز الدفع (2 مجموعات)

النوع: مضخة التروس.

6. جسم قالب الغزل (2 مجموعات، تصميم CL الأحدث)

طريقة توزيع الذوبان داخل الصندوق: مضخة واحدة، نوع شماعة واحدة

مزود بنظام تسخين وعزل أوتوماتيكي ونظام تحكم بعرض الضغط خلف الشاشة (في إشارة إلى شاشة الفلتر)، يعتمد التحكم في درجة حرارة كل منطقة على وحدة تحكم في درجة الحرارة، ومرحل الحالة الصلبة، ومقاوم حراري بلاتيني PT100 لتشكيل نظام حلقة مغلقة للتحكم في درجة الحرارة. يمكن لكل صندوق دوار توزيع المصهور بشكل متماثل ومتساوٍ. مزود بأدوات متخصصة وأجهزة نقل لسهولة استبدال المكونات.

7. جهاز شفط المونومر (2 مجموعات، تصميم CL الأحدث)

صف مزدوج ومتوازي مع أنابيب متعددة.

8. جهاز غرفة التبريد (2 مجموعات، تصميم CL الأحدث)

يعتمد على هيكل جديد لنفخ الهواء العرضي، الإطار الرئيسي مصنوع من مادة الألمنيوم، ولوحة ختم من الفولاذ المقاوم للصدأ مع عزل حراري.

9. وحدة الشد (2 مجموعات، تصميم CL الأحدث)

يعتمد على هيكل مجرى الهواء الممتد الجديد مع العزل الحراري.

تتكون لوحة الغطاء من لوحة فولاذية مقاس 2 مم، والتي من المطلوب أن تكون سهلة التفكيك والتجميع.

10. ناشر (2 مجموعات، تصميم CL الأحدث)

يمكن تعديل عرض قناة الانتشار عبر الإنترنت.

11. جهاز تشكيل الشبكة (1 مجموعة، تصميم CL الأحدث)

حزام الدوران: قطعتين

واحد للاستخدام أثناء التشغيل، والآخر للاستخدام بعد اكتمال التشغيل)

12. بكرة الضغط الساخنة (2 مجموعات)

13. بكرة الدعم (2 مجموعات)

يجب ألا تقل صلابة طبقة المطاط على سطح بكرة الدعم عن SHA76. يجب أن تكون أقصى ضغط للخط 7N/mm.

14. هيكل جهاز تشكيل الشبكة:

سماكة لوح الجدار 40 مم. حماية بألواح غطاء على الجانبين. يجب ضمان التوازي لمحور جميع البكرات وعمودية خط الوسط لجهاز تشكيل الشبكة لتحقيق الاستقرار العالي السرعة. جميع مجاري تشكيل الشبكة تعتمد على طريقة الشفط من جانب واحد.

15. مكلدر الأسطوانة المزدوجة (1 مجموعة) (علامة CL التجارية، بما في ذلك نظام التحكم وفرن الزيت الحراري)

سرعة الماكينة: 450 م/دقيقة.

شكل الأسطوانة: الأسطوانة العلوية هي أسطوانة بنمط مطبوع، والأسطوانة السفلية أسطوانة ملساء. العرض الفعّال للنمط على الأسطوانة المطبعة هو 3,700 مم. عرض الأسطوانة الملساء هو 3,800 مم.

16. جهاز اللف (1 مجموعة)

العرض الفعّال للعمل: 3,700 مم.

طريقة اللف: لف الاحتكاك.

طريقة تغيير البكرات: أوتوماتيكية.

17. جهاز التقطيع (1 مجموعة)

العرض الفعّال للعمل: 3,700 مم.

السرعة الميكانيكية: 30-900 م/دقيقة (نطاق تعديل العملية العادي: 30-800 م/دقيقة).